Desining

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Omnis esse odit modi, neque laboriosam sed, nam soluta impedit, voluptate reprehenderit enim totam consectetur tempore debitis.

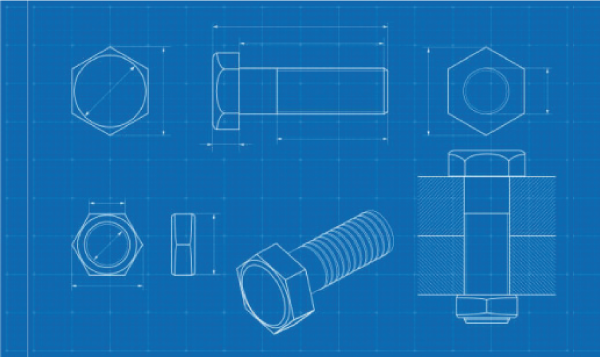

Nik Fasteners is an expert for high-quality fasteners, and offers engineering solutions based on the wide product portfolio

Truly customer-centric and providing the best-in-class Fasteners solutions to various segments of industries

Domestically produced fasteners are our essence of working and we use modern machineries to give you international quality.

The fasteners go through strict quality checks at every workstation to achieve maximum quality in our products

NIK FASTENERS was started to capture the Make in India ethos and ride the new wave of growth and optimism in the manufacturing sector of the country. A vacuum of high quality fastener manufacturers was identified, as there are very few suppliers who can cater to the specific requirements of the various user industries in a timely manner.

Our state-of-the-art plant is located in Barhi, Haryana (NCR) in a state industrial area with self- owned shed space of approx. 10,000 sq ft. We are currently manufacturing screws from size M2 to M6 with expansion plans underway. The plant has international technical tie-ups for product development, very well equipped tool room, an experienced team and a robust supply chain to ensure a seamless experience for our customers.

Discover MoreOur unwavering belief is that quality and consistency are the pillars of success. Hence we follow every possible measure to ensure the highest levels of quality. Our standard room is equipped with testing equipment such as Hardness tester, surface plate, height gauge and other high accuracy specialised instruments. We have the latest designing software inhouse and use the newest in CAD to visualize and develop our customers requirements. We have an extremely competent engineering team, especially in the manufacturing of precision parts.

Our mission is to produce and continually develop quality products at competitive prices while fostering a climate where innovation and new technologies can thrive.

We will always strive to service our customers with the utmost integrity, and to their complete satisfaction.

Our immediate future plan includes increasing capacity of our current range as well as expanding our range to include more sizes and other precision parts.

We always Aim to forge long-lasting relationships with our customers and channel partners.

our best vision

Uncoiled, straightened and cut to length.

Moulding the steel into the right shape at room temperature.

Progressively formed by forcing the steel into various dies at high pressure.

Threads are formed by rolling or cutting.

The bolt is exposed to extreme heat to harden steel.

Depends on the application. Zinc-plating is common to increase corrosion resistance.

our best service

Nik Fasteners can offer the following quality controls and checks as per customer requirement:

what we create

Basic knowledgebase

Bolts are fasteners engineered to be used with nuts to hold materials together.

The standard bolt measurement includes the thread diameter, thread pitch, and length.

The type of bolt you need will depend on the items you are connecting (ex. Materials, size, diameter, environment).

You can shop Bolts right here.

The numbers and letters on a bolt may be the manufacturer markings and/or the grade of the material.

A bolt is installed by drilling a hole into wood and then driving the screw in with a socket or wrench.

Our engineering skills and ingenuity are frequently utilised in developing prototypes

Before almost anything else, a manufacturing company must gain access to material resources to create their product and profit. When the correct resources are available in the appropriate quantities at production time, factories can work efficiently and with a minimum backlog.

Our unwavering belief is that quality and consistency are the pillars of success. Hence we follow every possible measure to ensure the highest levels of quality.

Materials are packed in corrugated boxes and dispatched on wooden Euro pallets to export customers. These pallets are fumigated, wrapped, labelled and strapped prior to dispatch.

We spent a fair amount of time searching for a bolt manufacturing company that we felt comfortable with; and we are glad that we chose NIK FASTENERS. Never could we imagine such quality & support, it's taken our business to a whole other level.

With NIK FASTENERS products' quality is one thing but service is what matters more, and this is proved by them time and again. Never has our production suffered because of poor supplies from them, whether it counts on time or quality.

PLOT 510, PHASE-2, HSIIDC

BARHI INDUSTRIAL AREA,

SONIPAT - 131 101,

HARYANA, INDIA.

MBA-IIM Ahmedabad

Director

+91-8128364803

keshav@nikfasteners.com